Green Philosophy

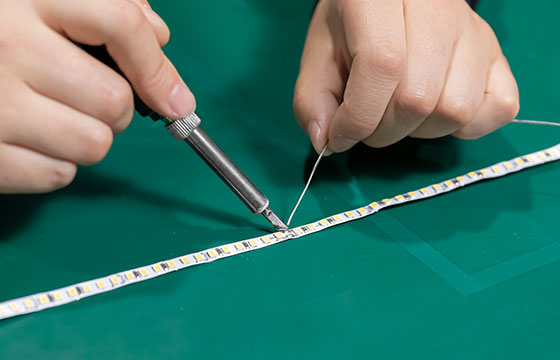

LED neon flex itself is environmental-friendly, yet we make it even greener from materials to production. The certifications of RoHS, REACH, UL, and CE are well maintained in each product series of ours.

Ginde Star is highly aware of our social responsibility and the LED lighting development trends. Hence our team always endeavors to optimize every manufacturing process to reduce our carbon footprint or any negative impact to the environment, and significantly improve our lean efficiency.